Environmental Product Declaration

Environmental Product Declaration (EPD)

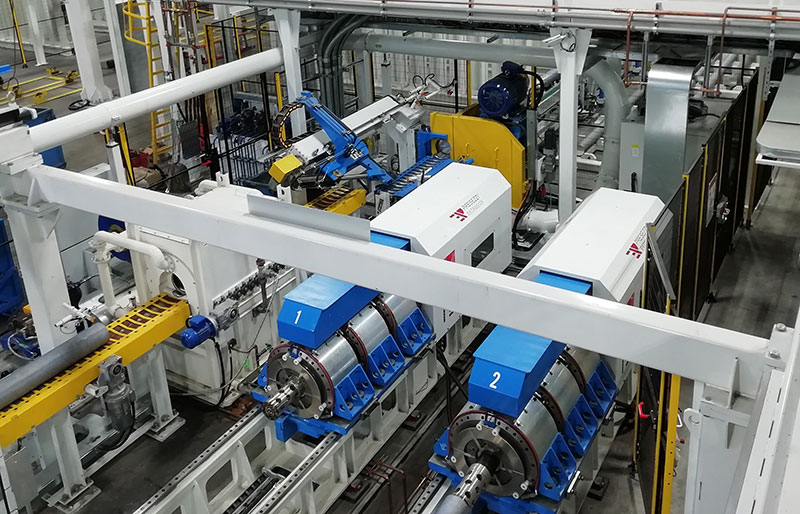

Presezzi Extrusion Group has proven experience in the production and commissioning of extrusion lines for non-ferrous metals, in particular in the aluminium field.

Founded 30 years ago as a producer of extrusion presses for aluminium, copper and brass. Thanks to its ongoing commitment and investment in research and development, geared towards improving and making its machines increasingly efficient and sustainable, the Presezzi Extrusion Group today offers complete turnkey extrusion lines, as well as modern foundries for aluminium alloy logs.

The Group’s management policies have forever been based on ethical principles whereby energy efficiency and savings are considered essential components and the cornerstones of our engineering and production. It is no coincidence that we were the first in the world to voluntarily develop the environment label (EPD) for our products. EPDs are declarations that present clear, objective, and verified information regarding the environmental performance of a product, assessed over its entire life cycle.

To date, Presezzi Extrusion Group has published two EPDs for the products:

S-P-06355 Permanent Magnet Heater ZPE (Zero Pollution Energy)

an innovative magnetic induction heating system for billets of non-ferrous materials, where the only energy required is to drive the magnetic sectors.

POTENTIAL ENVIRONMENTAL IMPACT Global Warming Potential (GWP) 96 kg CO2eq*

* figure per tonne of heat-treated aluminium. In reference to ZPE 10", billet length 1500 mm

S-P-06388 Extrusion Press ESS (Energy Saving System)

an Energy Saving System applied to extrusion presses, allowing the reduced consumption of electrical power during production, and the improved yield and quality of the extruded profiles.

POTENTIAL ENVIRONMENTAL IMPACT Global Warming Potential (GWP) 87 kg CO2eq*

* figure per tonne of extruded aluminium in reference to press ESS 40MN 10", billet length 1500 mm

The aim is to offer and guide clients towards technologies capable of environmentally friendly production, without needing to renounce production performance and efficiency.

With the EPD, the Presezzi Extrusion Group seeks to facilitate the virtuous conduct of its clients, providing them with a tool that certifies the environmental impact of their product, not limited to merely its production but rather extended to the entire life cycle of the product itself.

Presezzi Extrusion Group uses the EPD to measure and clearly communicate the environmental performance of its products, expressed through various impact indicators such as: climate change, eutrophication, acidification, use of abiotic resources, water scarcity.

One of the key premises that prompted the decision to obtain the EPD is the possibility to determine, through said EPD, the total carbon dioxide equivalent consumption, and not just of the product, offering clients the possibility to objectively determine their own impact on the climate, and therefore also act constructively in order to reduce and/or completely eliminate it.

Obtaining these EPD certifications requires a very structured and accurate process aimed at acquiring key information needed to measure, monitor, and implement targeted actions to reduce the impact of products on the environment and climate.

The LCA is a procedure to quantify the potential environmental impacts generated by a product or service along the entire value chain. The LCA methodology therefore supports innovation, eco-efficiency, the circular economy and also the communication and marketing of more sustainable products.

The results of the LCA study are then carefully verified by an independent third party before being reported in the EPD, together with other information concerning the products under analysis, the company, and its environmental policies. Once ready, the EPD is registered and published on the Programme Operator's website and therefore available for anyone to consult.

Every day, Presezzi Extrusion Group demonstrates its commitment to handing over a better world to future generations: the constant search for innovative and sustainable technological solutions, and the obtainment of these certifications, are further proof of this.

More information is available at www.environdec.com.

Permanent Magnet Heater ZPE (Zero Pollution Energy)

Registration number: S-P-06355

Read certification

Extrusion Press ESS (Energy Saving System)

Registration number: S-P-06388

Read certification